WATER AND THERMAL INSULATION OF FOUNDATIONS

Proper insulation and waterproofing of foundations against the harmful effects of moisture are essential tasks. To avoid damage and consequently endangering the entire building structure, the best available materials and modern technology should be used. That’s exactly what you’ll find at our company, Bolix!

A CROSS-SECTION OF INSULATION ON A SECTION OF THE FOUNDATION FOOTING

A. FOUNDATION WALL

B. SOIL

C. BITUMEN WATERPROOFING

D. PROTECTIVE LAYER

BITUMEN WATERPROOFING FOR FOUNDATIONS

LIGHT-DUTY DAMP-PROOFING

Used in permeable soils (allowing quick absorption of rainwater into the soil below the foundation level), where the groundwater table is below the building’s foundation level.

MEDIUM-DUTY WATERPROOFING

Foundation waterproofing used in impermeable soils that prevent the quick absorption of rainwater, where the groundwater is below the foundations, and also in cases of temporary rises in groundwater levels above the foundation level.

HEAVY-DUTY WATERPROOFING

Foundation waterproofing used where the groundwater table is above the foundation level, regardless of soil type, including impermeable soils where rainwater (infiltrative water) remains around the foundations for an extended period, exerting pressure on the waterproofing. The purpose of the foundation waterproofing is to protect the foundations from pressurized water, which exerts hydrostatic pressure.

WATERPROOFING PROPERTIES

| PROPERTIES | BOLIX B-MB Emulsion | BOLIX B-1SM Express | BOLIX B-2SM Profi | BOLIX B-2SM Uni |

|---|---|---|---|---|

| TYPE OF WATERPROOFING | Single-component, thin-layer | Single-component, thick-layer | Two-component, thick-layer | Two-component, thick-layer |

| OPEN WORK TIME | x | x | Approx. 1.5 h | Approx. 1.5 h |

| APPLICATION AND DRYING TEMPERATURE | +5°C to +30°C | +5°C to +30°C | +5°C to +30°C | +5°C to +30°C |

| MASS THICKNESS LOSS DURING DRYING | Approx. 45% | Approx. 10% | Approx. 20% | Approx. 30% |

| DENSITY | 1.05 g/cm³ | 0.80 g/cm³ | 0.88 g/cm³ | 1.17 g/cm³ |

| RAIN RESISTANCE | 4 – 6 h | 8 h | 5 h | 7 h |

| HARDENING TIME | x | Min. 2 days | Min. 2 days | Min. 2 days |

| MAX. WET COATING THICKNESS | 6 mm | 6 mm | 8 mm | 8 mm |

| CRACK BRIDGING CAPACITY | x | 2 mm | 2 mm | 2 mm |

| REINFORCING FIBERS | x | x | x | Yes |

| SHELF LIFE | 12 months | 12 months | 12 months | 12 months |

EXTERNAL WALL INSULATION WITH EPS STYROFOAM PANELS

Separating the base part of a building is considered good practice, stemming from years of experience and observation, and is stipulated in the Regulation on technical conditions that buildings and their locations should meet, which states:

§ 317. 1. Basement walls of a building and other elements in contact with the ground, made of materials that “draw water” capillarily, should be protected with appropriate damp-proof insulation.

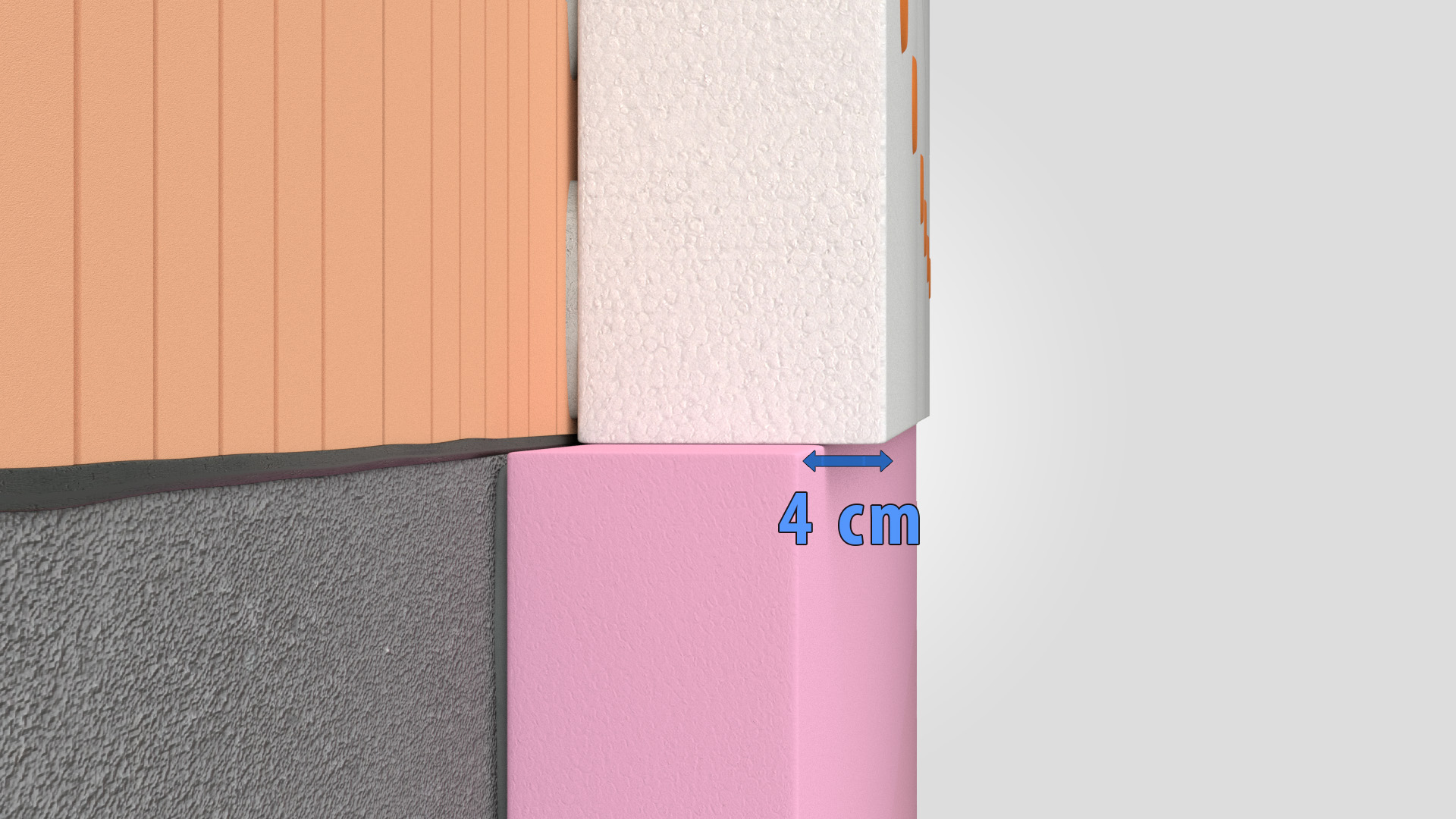

2. Parts of external walls, directly above the surrounding terrain, terraces, balconies, and roofs, should be protected against the penetration of rainwater and melting snow. In the lowest above-ground part of the building, it is recommended to separate the base part. The height of this element above ground level is usually around 30-40 cm. If thermal insulation in the base is in contact with the ground or below ground level, it is recommended to use XPS boards or perimeter EPS boards of the Foundation type with the lowest possible water absorption. It is recommended that the surface of the thermal insulation in the base be recessed by about 4 cm relative to the outline of the insulated wall. This is usually achieved by reducing the thickness of the thermal insulation but with a lower thermal conductivity coefficient λ so that the U coefficient remains at the designed level. This measure aims to minimize the risk of water seepage running down the façade or mechanical damage caused by building use, weather conditions, snow, or ice accumulation. If the insulation work also includes insulating the foundations (which is not the subject of this instruction), it is recommended to perform it in the first stage before starting the main insulation of the building’s façade.

Bituminous masses can be used to glue the insulation boards to the completed waterproofing. It should be applied to the XPS boards either spot-wise (evenly distributed blobs) or full-surface with a trowel (mandatory solution in the case of impounding infiltration water and pressing water) and then lightly pressed to the substrate. The boards should be laid in a staggered pattern, edge to edge. Protective and filtering layers can be applied only after the insulation layer has completely dried. Protective layers must not exert point or linear mechanical loads on the performed sealing.